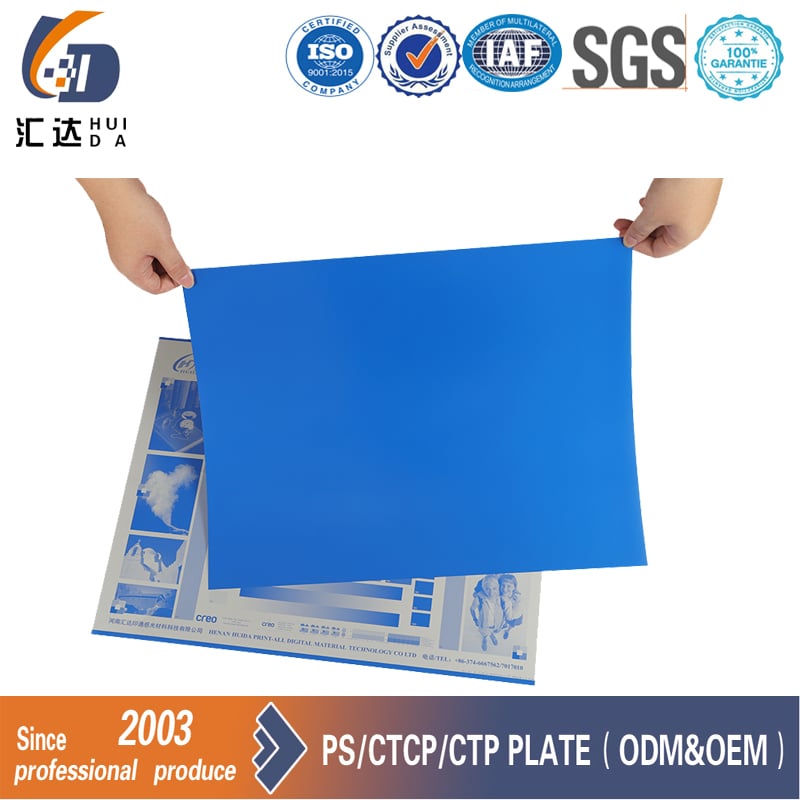

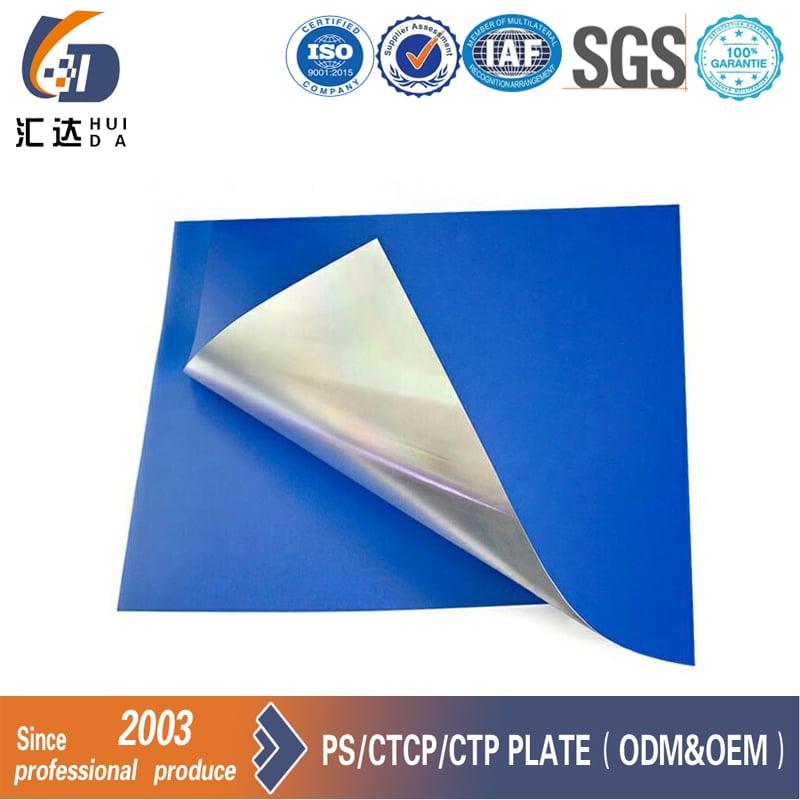

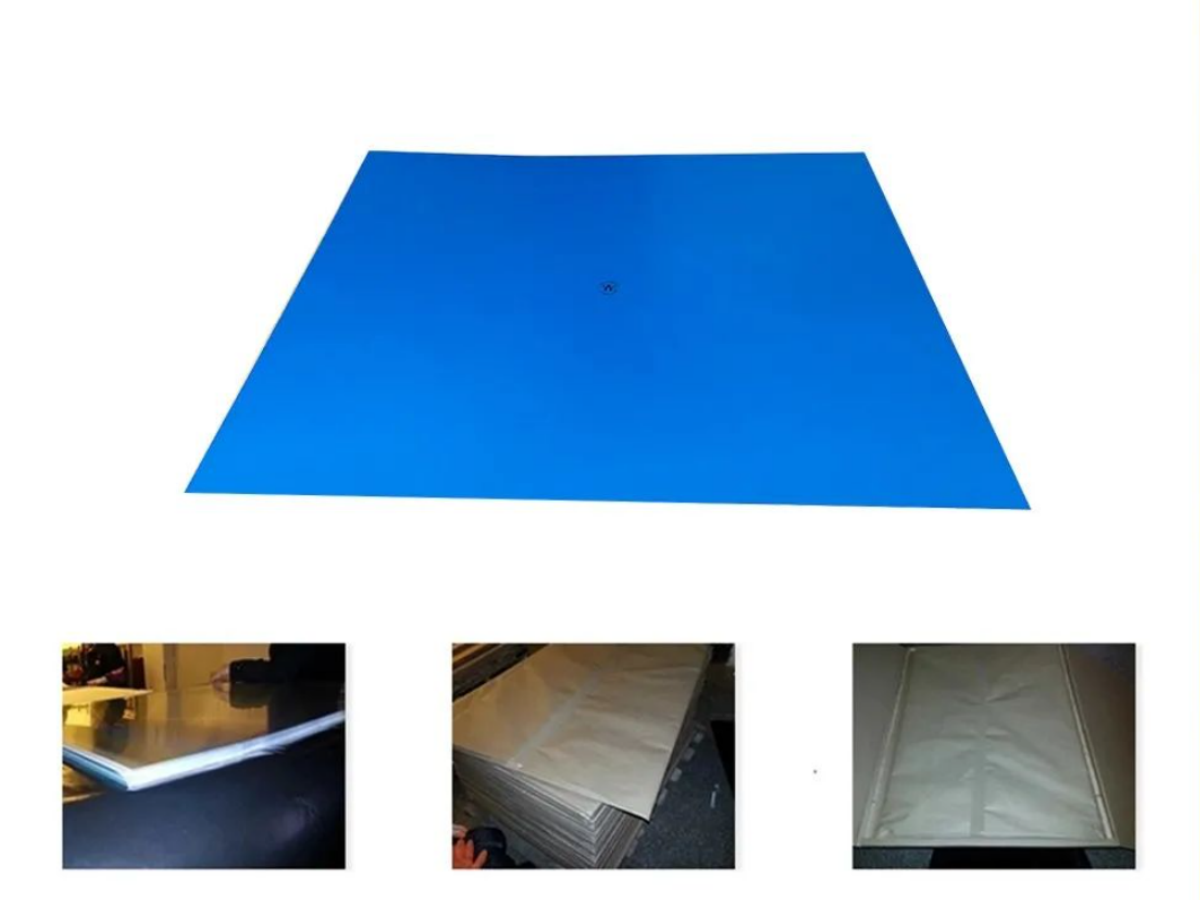

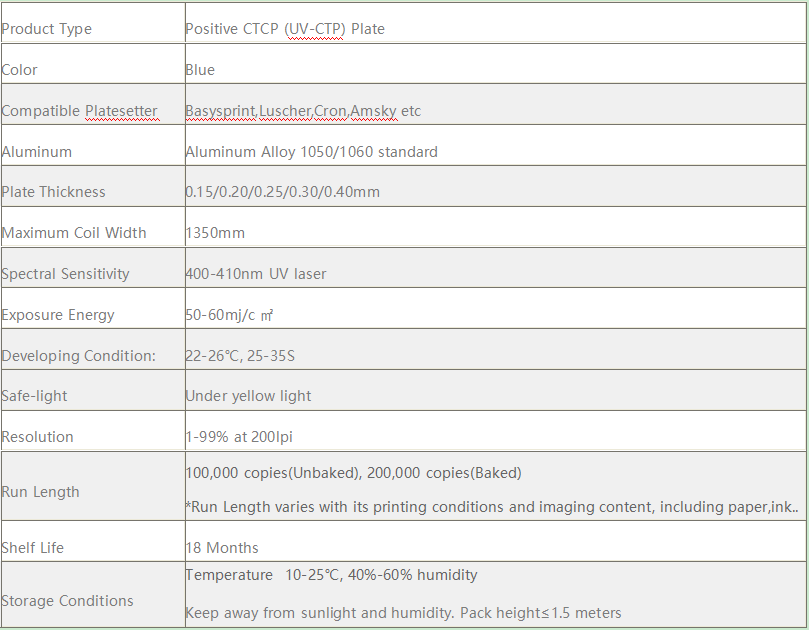

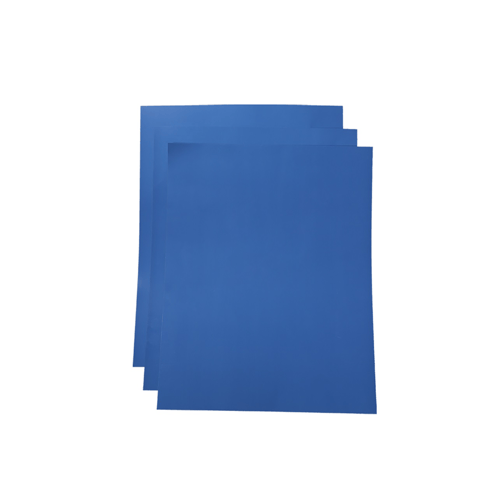

Offset Printing Plate

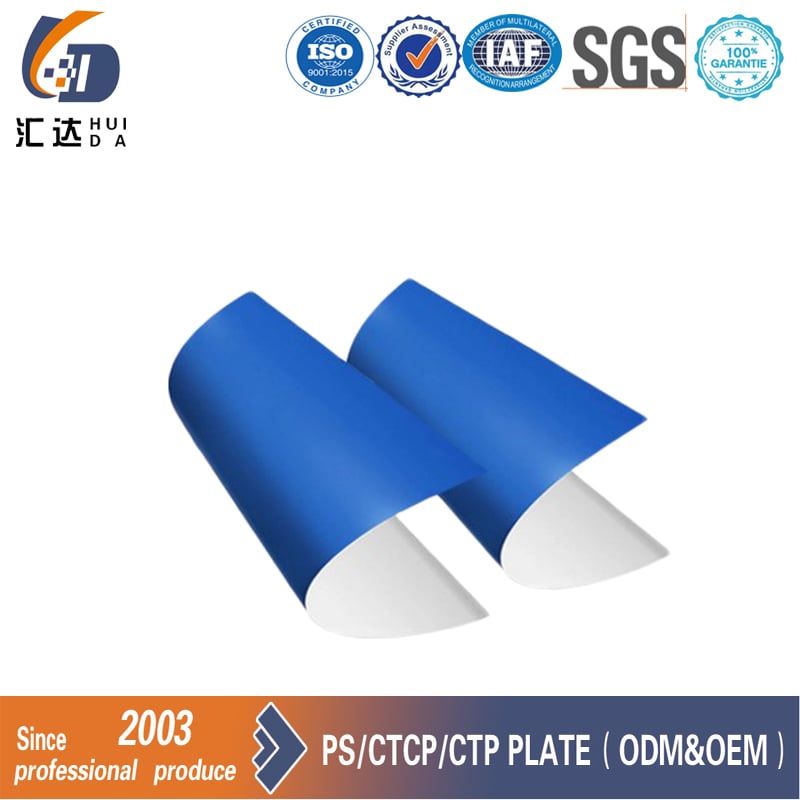

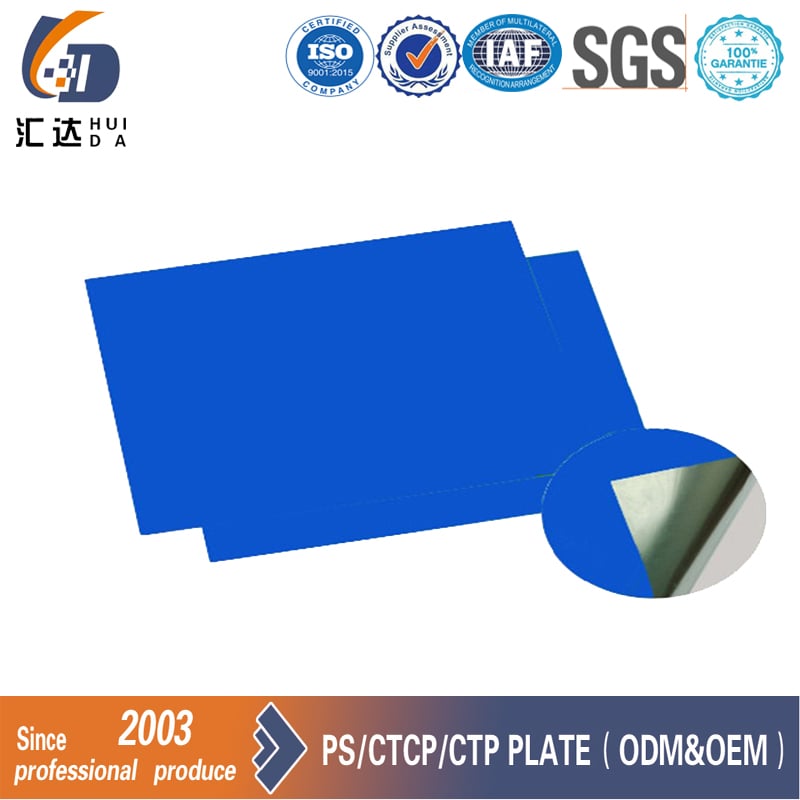

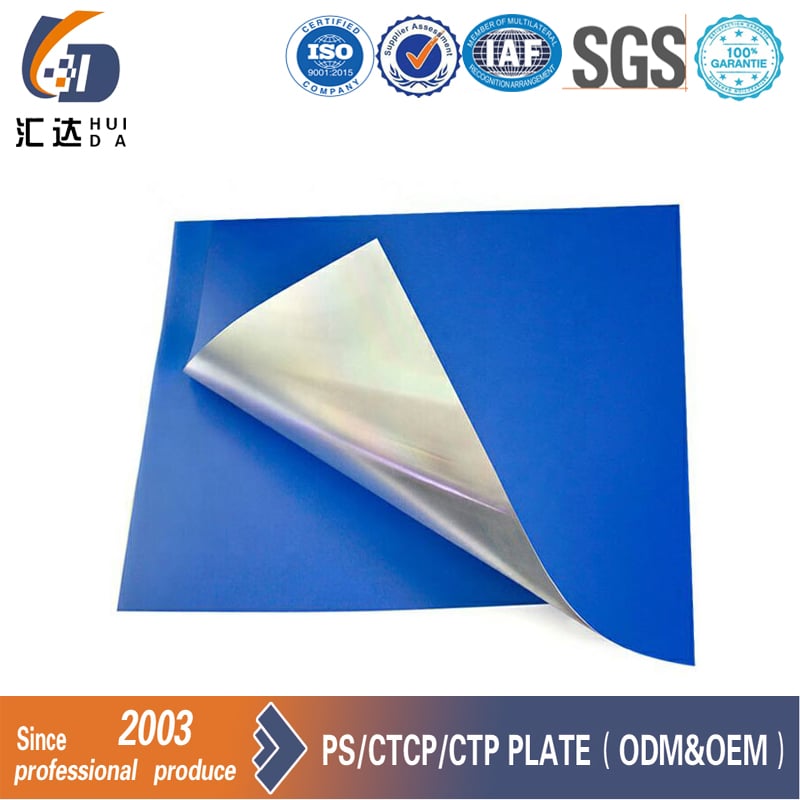

Suitable for various plate setter in offset printing and extensively used in commercial printing and newspaper printing. Whether conventional or alcohol wet plate can output clear, excellently, perfectly colorful prints.

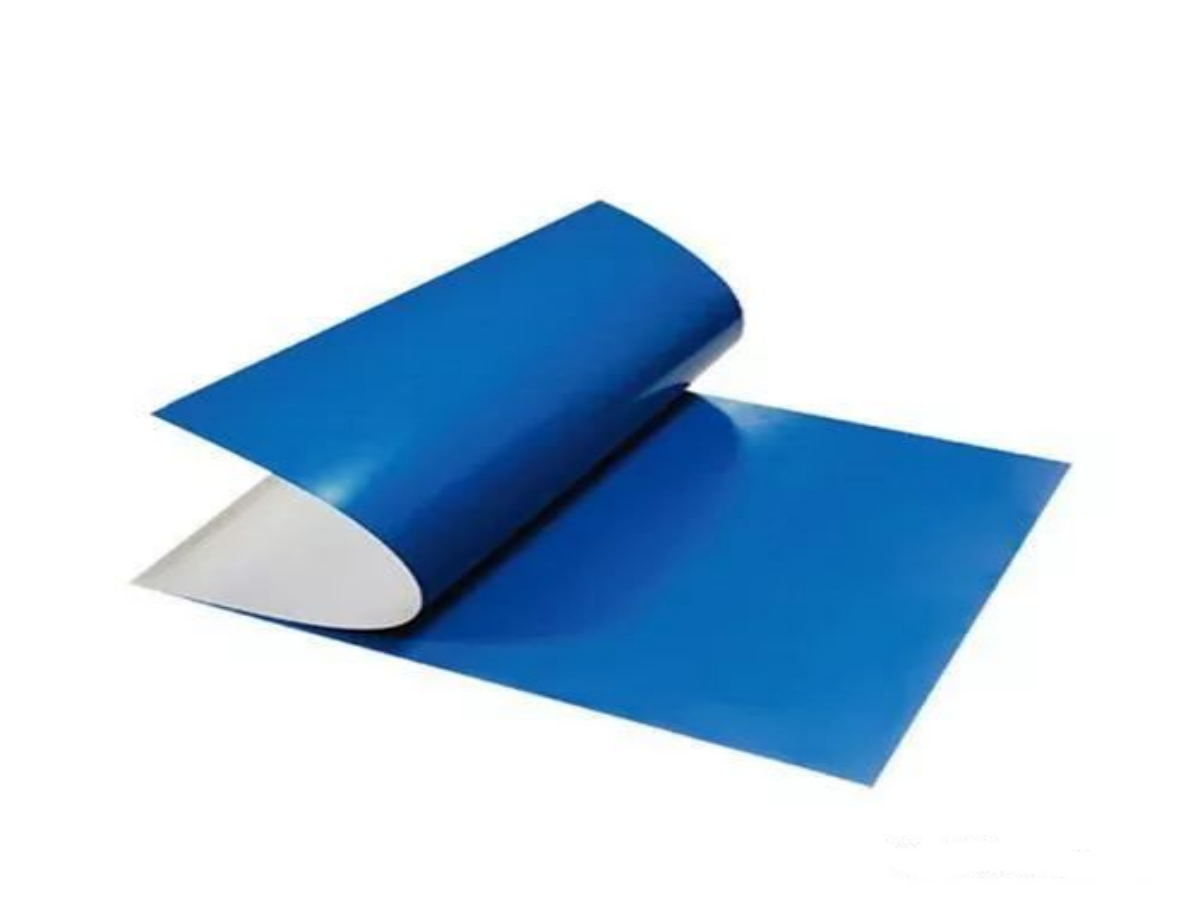

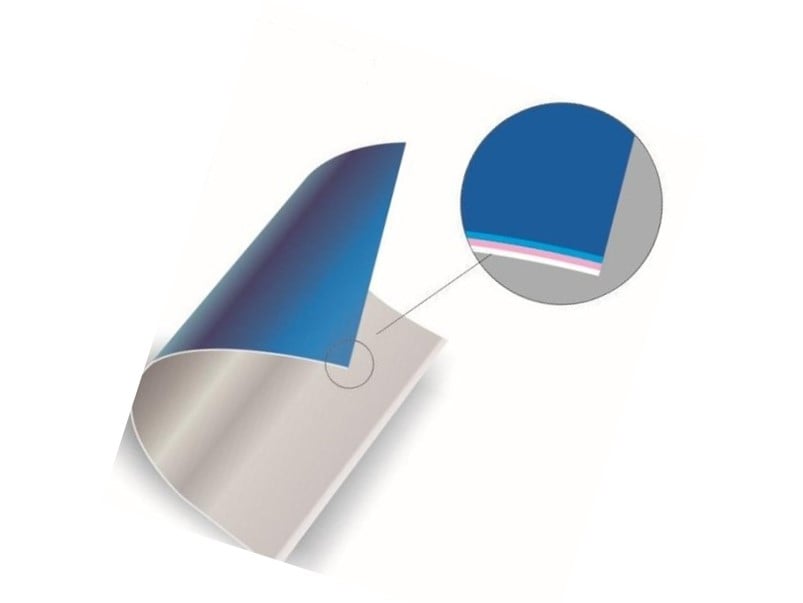

Multi layer grains, smooth coating, high sensitive speed, excellent dot reappearance, large exposure and developing latitude, quick ink water balance, long impression

Combining many excellent capacities, is designed with unique dobule coating formula, not only for UV ink printing, but also for ordinary ink printing, now has been ideal choice for medium and high-end printing user, hot-selling all over the world

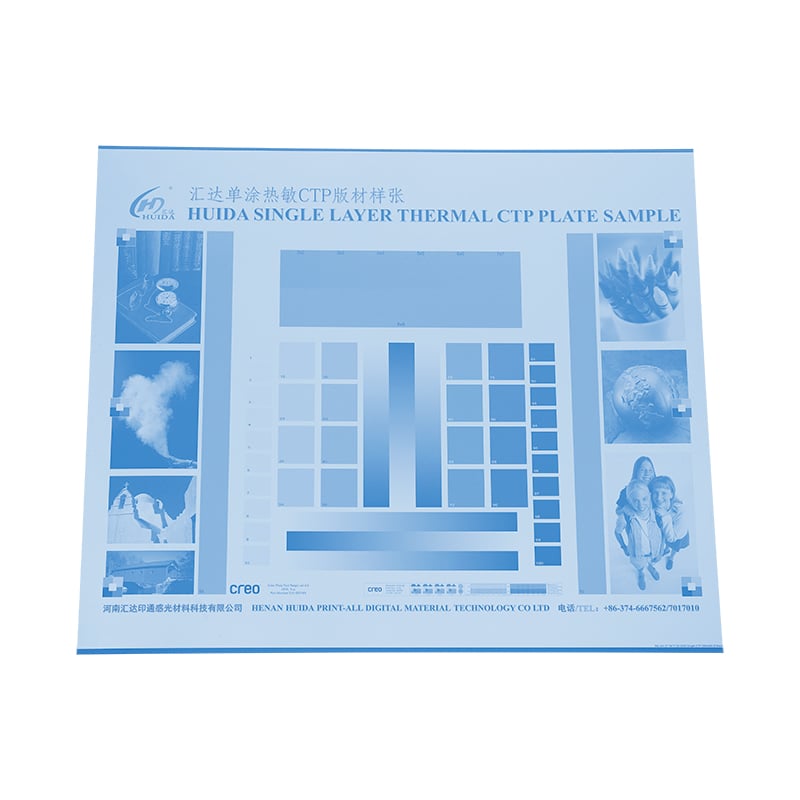

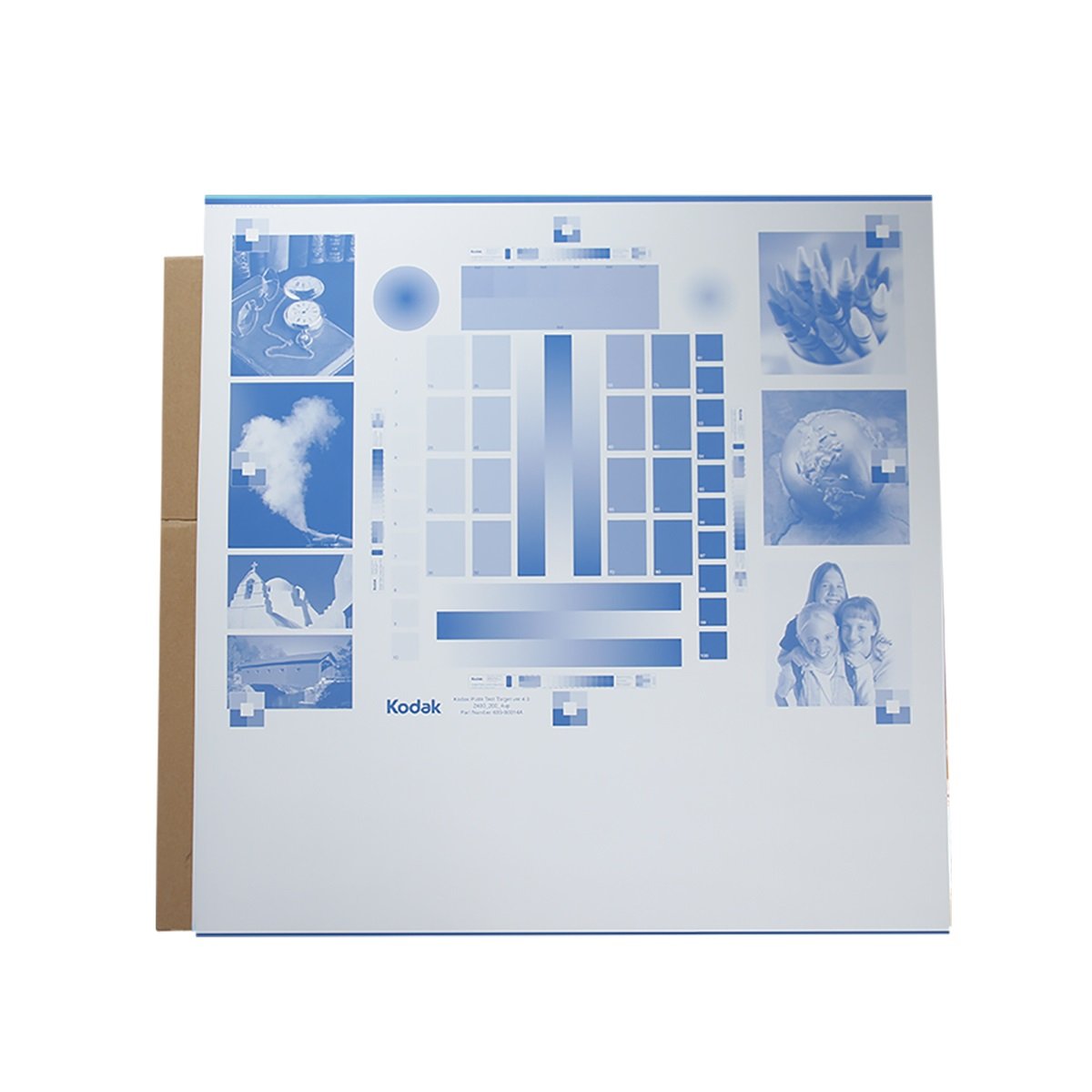

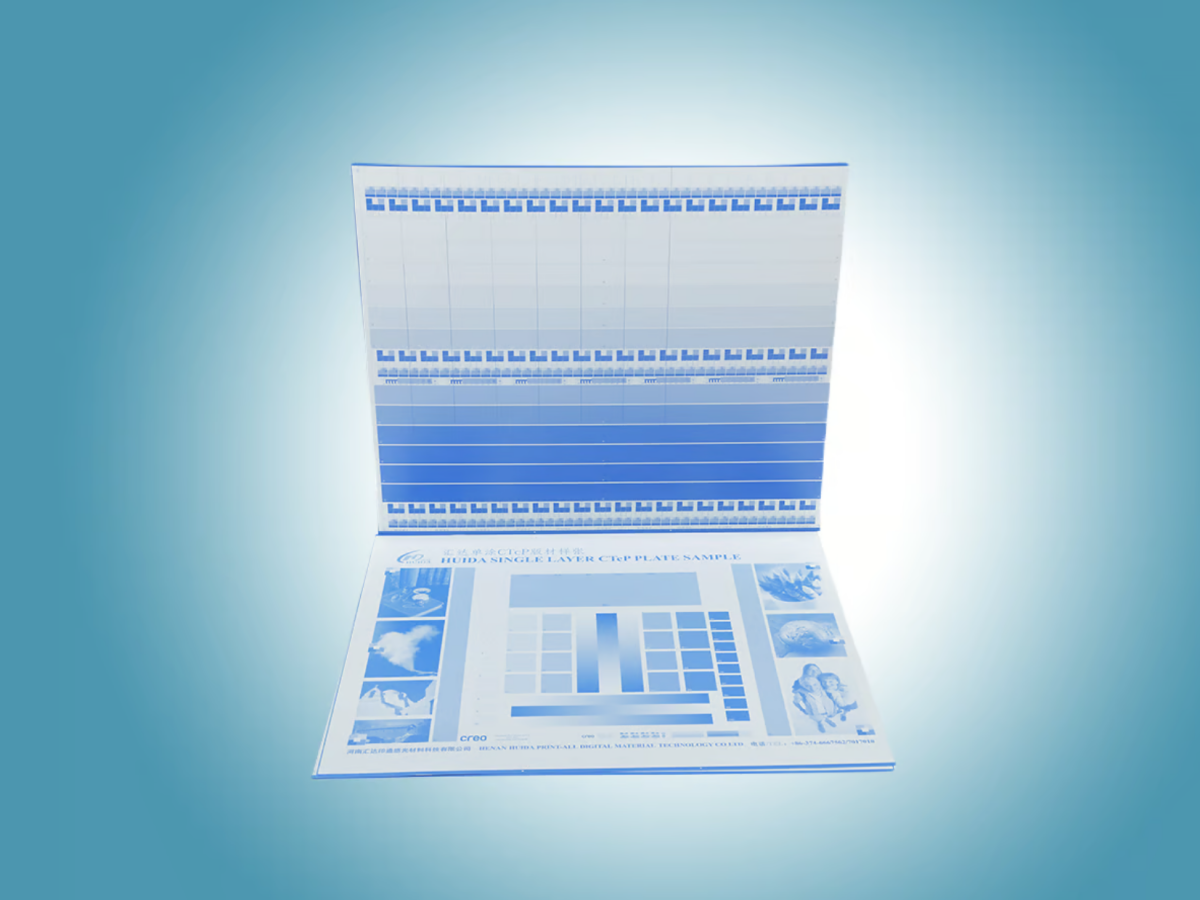

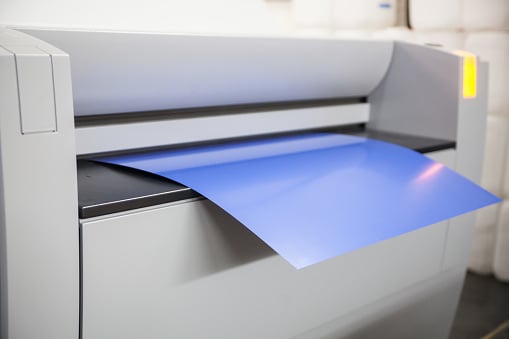

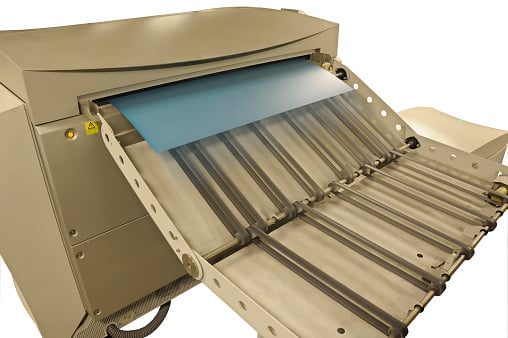

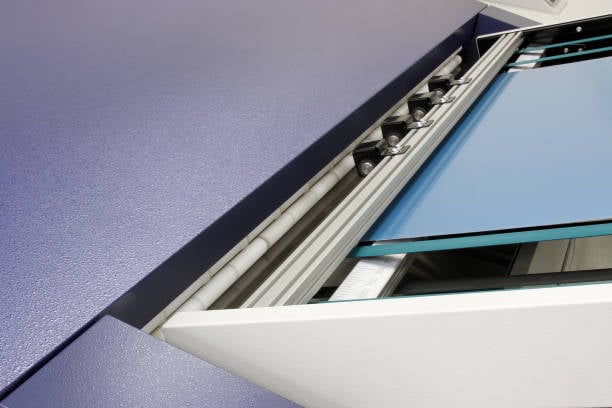

It is using for mass brand of thermal CTP plates, by working with automatic plate processor. Good compatibility, powerful and durable, full dot, leaving the film is high, no precipitation and crystallization

Close-grained Oxidation Layer –Outstanding dot reproduction, high resolution. Excellent Hydrophilicity- keep ink-water balance optimally. Unique Photosensitive Coating-High and fast Sensitivity.

The Benefits of Offset Printing

-

High Quality and True Color

Since Offset uses ink instead of toner (digital printing), the result of the print is a lot richer and clearer.

-

Low Cost

Medium to large quantity printing is best used with offset printing. The more quantities that are produced, the cheaper the per unit cost becomes.

-

Fast and Efficient

Web-fed can produce over 80,000 copies of printed materials while producing them in high quality.

-

Flexible and Dynamic

Offset printing works on a wide range of materials including paper, cardboard, wood, leather, and plastic while providing solutions to special finishes and other design requests.

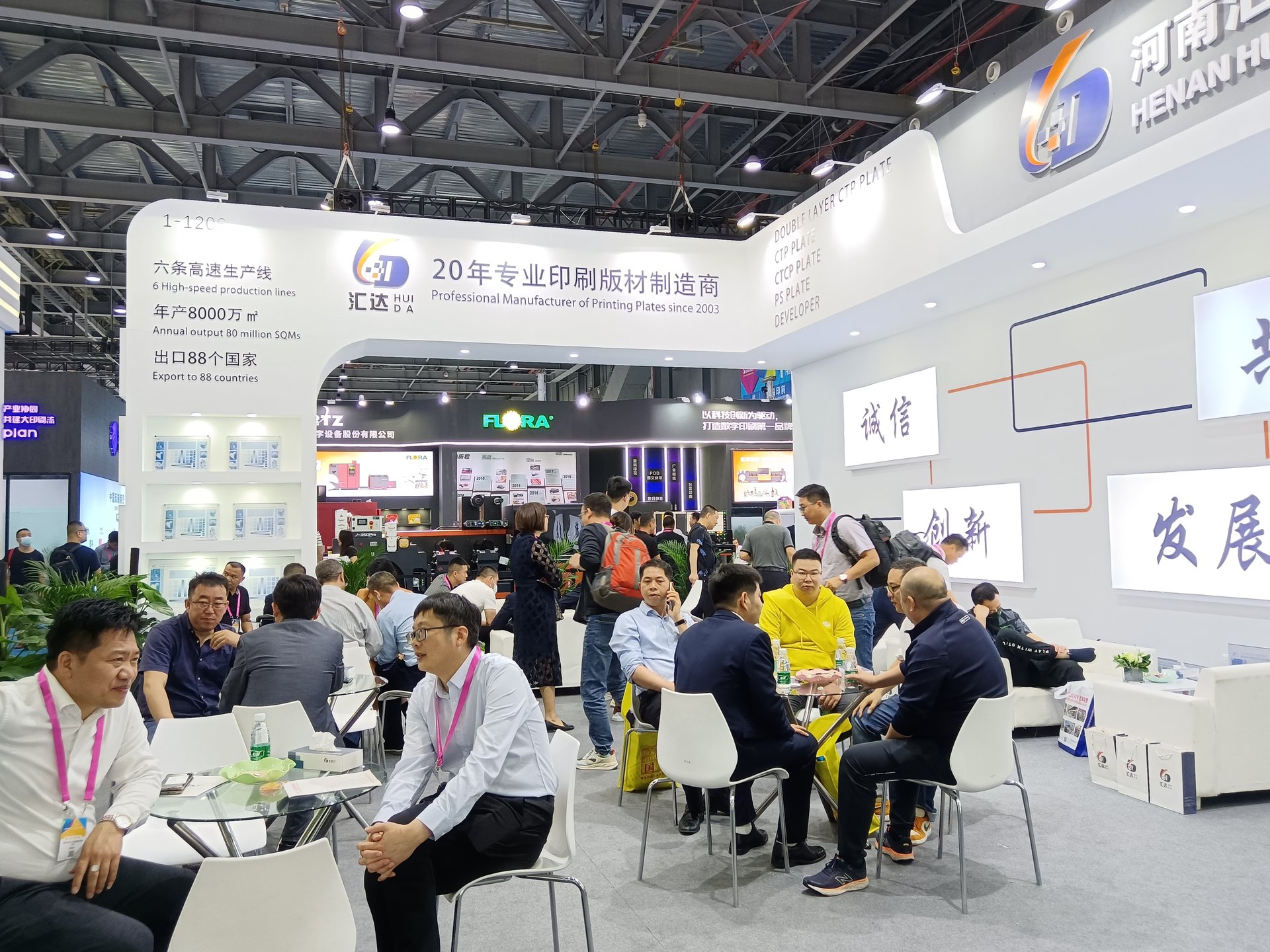

COMPANY PROFILE

Henan Huida Print-All Technology Co., Ltd. established in 2003, is a listed enterprise integrating R&D, production and comprehensive inspection of specialized and large-scale printing plate manufacturing. The company has 6 high-speed production lines with an annual output of 60 million square meters. The products are exported to dozens of countries in Europe, ASEAN, South Asia, America, and Africa.

10

+

New Research

6

+

Production Line

3000000

+

Daily Output

10

+

Exclusive Agents

Global Business

HUIDA ADVANTAGES

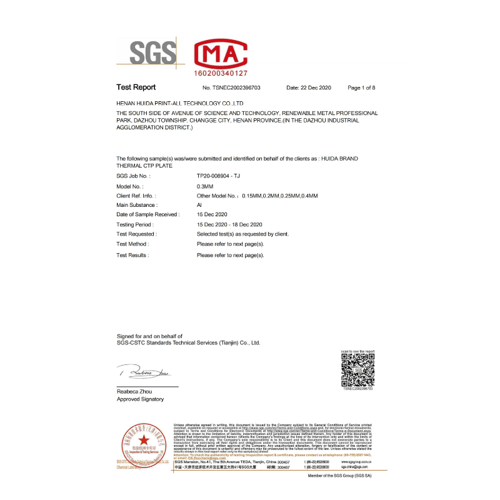

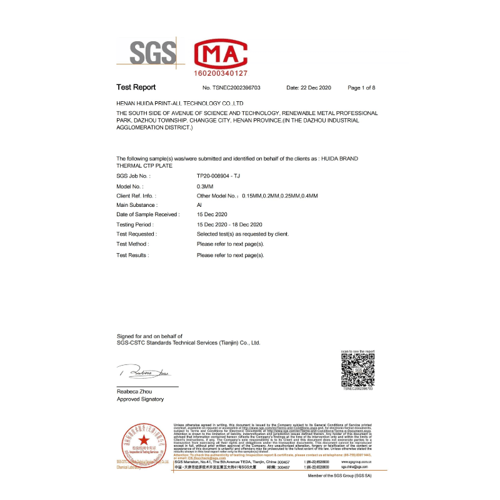

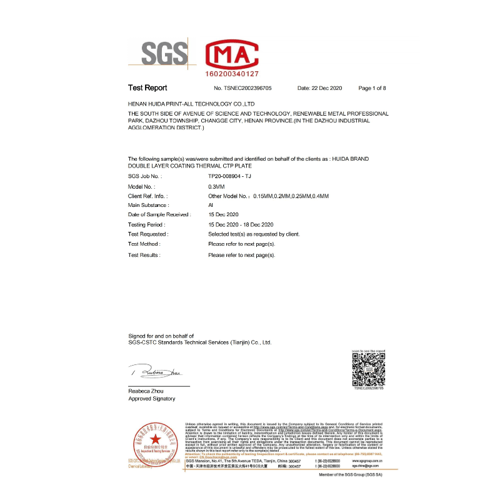

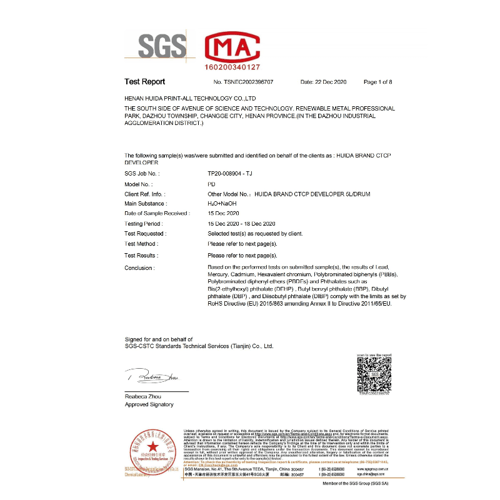

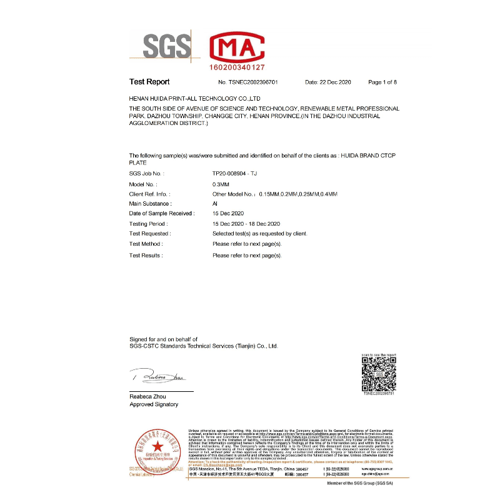

SGS certification refers to the service that SGS certifies the compliance of the target according to standards, regulations, customer requirements and other conditions. It is the world's largest and oldest private third party engaged in product quality control and technical appraisal

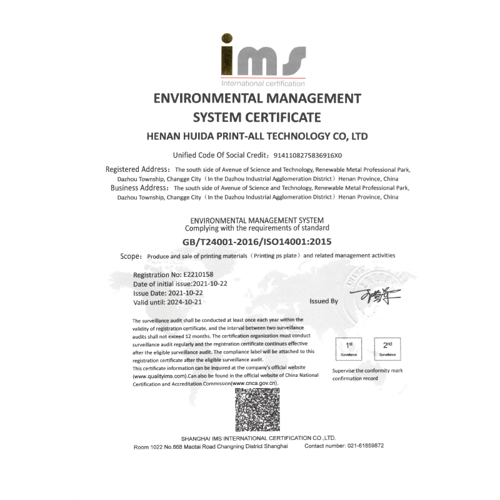

The ISO 9001 international quality management system standard is the most mature set of management systems and standards in the world so far, and it is the foundation for the development and growth of enterprises.

Read Our Latest News And Blog

Frequent Asked Question

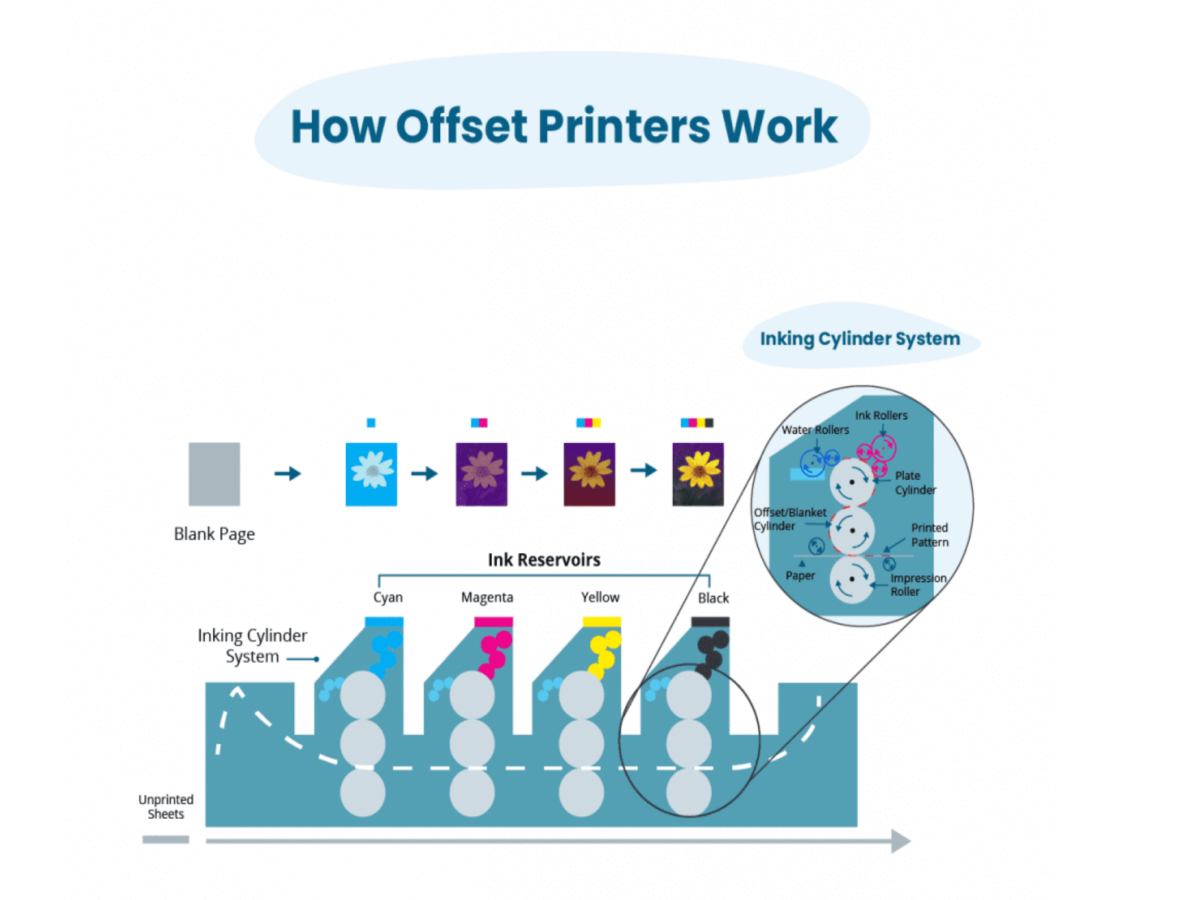

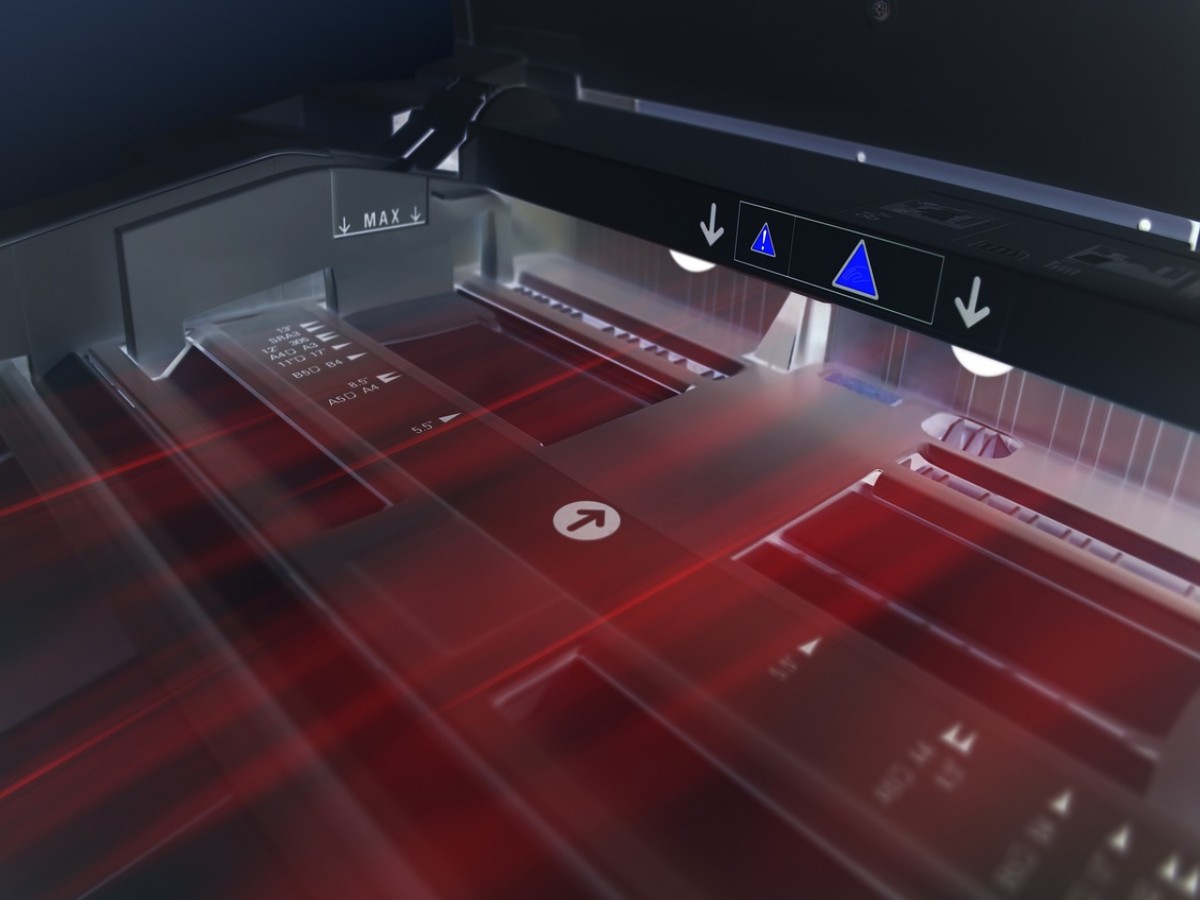

Offset printing technology or offset lithography requires aluminum plates to print an image onto a rubber "blanket," which is then rolled onto a sheet of paper. Since the ink is not transferred directly onto the paper, it is called offset printing. Because offset presses work so efficiently once they are set up, offset printing is the best choice when bigger quantities are required, and provides accurate color reproduction, and crisp, clean professional looking printing.

Offset printing is the original, durable, and time-tested option. It’s best for large to massive, cost-effective print runs. Plus, it guarantees excellent color options and the broadest range of surface print materials.Digital printing is a lightweight and cost-effective choice for low print runs. It's difficult to beat because of its quick turnaround and seamless adaptability. Not to mention the constant advancement of the fresh, inventive technology.

Offset printing, also called offset lithography, or litho-offset, in commercial printing, widely used printing technique in which the inked image on a printing plate is printed on a rubber cylinder and then transferred (i.e., offset) to paper or other material.

Cheaper for Larger quantities: If you are doing a large run of a project, offset printing will save you money. The price per piece is actually cheaper than digital.

Offset lithography is one of the most common ways of creating printed materials. A few of its common applications include: newspapers, magazines, brochures, stationery, and books.

First, your images are digitally transferred onto a set of plates, which collect ink to transfer your images onto a rubber blanket that transfers images onto paper. There are two primary types of offset printing: sheet-fed and web. The most common alternative to offset printing is known as digital or print-on-demand.

- Choosing a selection results in a full page refresh.