As the printing industry continues to evolve, so does the technology used in the process. Computer-to-plate (CTP) technology is one such advancement that has revolutionized the way printing plates are made. CTP technology has replaced the traditional process of creating printing plates by making use of film negatives. CTP plates offer several advantages over conventional plates, including improved image quality, faster turnaround times, and cost savings.

If you are in the market for CTP plates, it is essential to understand how they work and the factors to consider when choosing the right CTP plate for your needs. In this comprehensive guide, we will delve into the details of CTP plates and how they work for offset printing, compare the pros and cons of different types of CTP plates, and discuss the essential factors to consider when selecting the right CTP plate for your printing needs. We will also look at the steps to prepare your digital files before sending them for plate making.

What Are CTP Plates and How Do They Work for Offset Printing

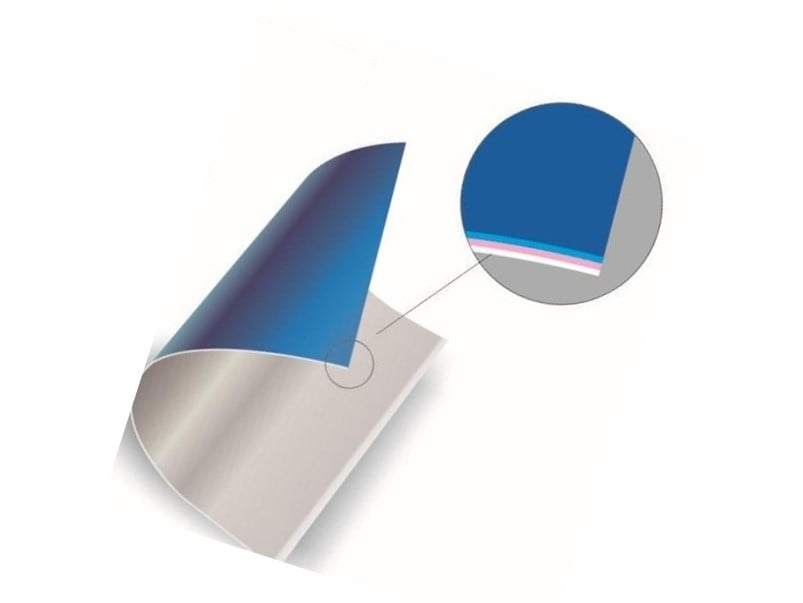

CTP plates are aluminum plates that are used in the offset printing process. These plates are coated with a light-sensitive emulsion that reacts to laser light to create an image. CTP plates are exposed to laser light that removes the coating in areas where the image is to be printed. The exposed plate is then developed to remove the unexposed areas, leaving behind the image on the plate surface.

CTP plates offer several advantages over traditional film-based plates. Firstly, they eliminate the need for film negatives, which reduces the time and cost of the printing process. Secondly, CTP plates offer superior image quality and consistency, as the digital files can be fine-tuned for accuracy and color correction. Thirdly, the plates are more durable, which leads to longer print runs without the need for re-plates.

Comparing the Pros & Cons to Choose the Best CTP Plate for Your Needs

There are two types of CTP plates available in the market – thermal and violet. Each type of plate has its own set of advantages and disadvantages that need to be considered when selecting the right plate for your needs.

Thermal CTP plates use heat to create an image on the plate surface. The plates are sensitive to heat, and the areas that are exposed to the laser light become receptive to ink during printing. The main advantage of thermal plates is that they offer fast plate making times and excellent print quality. The downside is that they are more expensive than violet plates and are not as environmentally friendly.

Violet CTP plates use a violet laser to create an image on the plate surface. The plates are sensitive to violet light, and the areas that are exposed to the laser light become receptive to ink during printing. The main advantage of violet plates is that they are less expensive than thermal plates and are more environmentally friendly. The downside is that they have slower plate making times and are not as forgiving in terms of image quality as thermal plates.

At present, Huida's main CTP plates are thermal plates, which have two types: single layer thermal CTP plates and double layer thermal CTP plates. They respectively have these features:

Single layer thermal CTP plate:

Huida Single Layer Thermal CTP plate is newly-updated by exclusive coating formula, with following advantages:

Easy-to-use;

Able to work under white light and no need to pre-heating;

Steady Quality, Good Compatibility, Excellent dot reappearance, Long Run-length;

Close-grained Oxidation Layer –Outstanding dot reproduction, high resolution;

Excellent Hydrophilicity- keep ink-water balance optimally;

Unique Photosensitive Coating-High and fast Sensitivity.

Double layer thermal CTP plate:

The plate is designed and manufactured with the formula of high-quality aluminum plate base and double coating, with the following advantages: UV resistant ink, strong stability, large development tolerance, high printability, good dot reducibility and stable performance.

Learn more: The Benefits of Double Layer Thermal CTP Plates for Professional Printing

What Are the Essential Factors to Consider When Choosing a CTP Plate

When selecting the right CTP plate for your printing needs, there are several factors that need to be considered. These factors include:

Printing Volume – The printing volume will determine the durability of the plate. For high-volume printing, you will need a more durable plate that can withstand longer print runs.

Plate Type – The type of plate will depend on your printing needs. If you require fast plate making times, thermal plates may be the best option. If you are looking for a cost-effective solution, violet plates may be a better choice.

Image Quality – The image quality required for your printing needs will also determine the type of plate required. If you require high-quality, fine detail images, thermal plates may be the best option.

Substrate – The substrate is the material that the printing will be done on. The type of substrate will determine the type of CTP plate required. For example, if you are printing on non-porous substrates like plastic or metal, you will need a thermal plate.

Plate Size – The size of the plate required will depend on the size of the printing press and the size of the printing job.

Budget – Budget is a critical factor when choosing the right CTP plate. The cost of the plate will depend on the type of plate, the size, and the printing volume.

Environmental Impact – The environmental impact of the plate is an important consideration for many printing companies. Violet plates are more environmentally friendly than thermal plates as they require less energy to make and produce fewer emissions.

How to Prepare Your Digital Files Before Sending Them for Plate Making

Preparing your digital files before sending them for plate making is critical to ensuring that you get high-quality prints. Here are some steps to follow:

Convert Files to CMYK – Convert your files to CMYK color mode before sending them for plate making. This will ensure that the colors in the print match the colors in the digital file.

Check Image Resolution – Check the image resolution of your files. For offset printing, the minimum resolution required is 300 dpi. If the resolution is lower, the image may appear blurry or pixelated in the print.

Embed Fonts – Embed the fonts in your files to ensure that the fonts appear correctly in the print.

Add Bleed – Add bleed to your files to ensure that the design goes to the edge of the printed piece. Bleed is the area outside the final trim size of the printed piece that will be trimmed off after printing.

Check for Errors – Check your files for any errors or typos before sending them for plate making. Any mistakes in the files will appear in the print.

In conclusion, selecting the right CTP plate for your printing needs is critical to ensuring that you get high-quality prints that meet your requirements. When choosing a CTP plate, consider factors like printing volume, plate type, image quality, substrate, plate size, budget, and environmental impact. Additionally, preparing your digital files correctly before sending them for plate making is crucial to achieving high-quality prints. With the right CTP plate and proper file preparation, you can create stunning prints that exceed your expectations.

About Huida

Henan Huida Print-All Technology Co., Ltd, established in 2003, is specialized in manufacturing large-scale printing plates. The company has two production bases with a registered capital of 50 million CNY and the investment scale is 600 million CNY. The Huida factory is located in Dazhou Industrial Park, Changge City, Henan Province, which is adjacent to Beijing-Guangzhou Railway, No.107 National Road, Beijing-Hong Kong-Macao Expressway, and 40 kilometers away from Zhengzhou International Airport in the north. It has a superior business environment and obvious regional advantages.

The company has four high-speed production lines, the main products include CTCP(UV-CTP) Plate, Single Layer Thermal CTP Plate and Double Layer Thermal CTP Plate. At present, the annual output is 40 million square meters. The product performance has reached international standards and has been recognized and praised by the market. The domestic market share is over 10%. At the same time, Huida brand printing plate has exported to dozens of countries in Europe, Southeast Asia, America, and Africa. In addition, the second production base is under rapid construction, it includes four production lines. The future is promising.

The company's products use high-quality aluminum plate base and international advanced multi-layer graining technology. The quality of the product is stable, and it has good graphic hierarchy reproduction with the high resolution and long run length. The product quality has reached the HG/T2694-2003 standard and passed the ISO-9001 international quality system certification.

If you are hunting for a suitable CTP plate, contact us immediately!

Email: mailto:[email protected]

Tel/Whatsapp: +86 15637430106

Facebook: Henan Huida Print All Technology Co.Ltd