For those of you unfamiliar with the term, offset printing plate in Melbourne operates according to the principle that oil and water do not mix. The process is begun by burning an image into a plate – the areas that are burned attract ink, whilst the areas that clearly attract water. The plate is placed onto a printing press where it receives water and ink; the image is then imprinted onto a rubber mat. Paper is pressed against the mat, which transfers the image onto it.

There are several types of plates that could be used for the offset printing process, and some of these include:

Diazo Coated

These plates are coated with an organic compound known as diazo. This allows the plate to hold up on short press runs (anything less than 250,000 paper impressions) with ease.

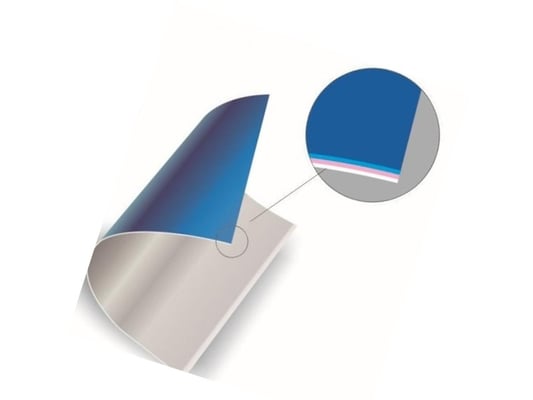

Photopolymer Coated

These plates are coated with another organic compound known as photopolymer. This improves the plate’s ability to withstand abrasions and resist wear. It is ideal for longer runs (anything up to one million impressions) and is the most popular type in use.

Silver Halide

These plates are coated with a photosensitive material that is similar to that which coats photographic film. This is only suitable for shorter press runs (of up to several thousand impressions) and is ideal for single color jobs. During processing, the silver coating is removed.

Electrophotographic

These offset printing plates are treated in a way that allows the image area to attract a toner-type ink coating (the ink is similar to that used in toner printers). This type is typically used for two-color jobs and is placed inside printing duplicators.

Waterless

These plates have a layer of silicone applied to their surface. This layer only adheres to the non-ink receptive parts of the plate, thereby meaning that the water (which is normally used to keep the ink confined to the image layer) is no longer needed.

As you can see, there are a number of plates that could be chosen for use in offset printing in Melbourne – each possesses advantages and disadvantages, resulting in the need to assess jobs on a case-by-case basis. As we have already pointed out, however, photopolymer coated plates are the most common type because they are so sturdy and versatile. If you would like to use a different plate for whatever reason, please discuss this with your printer.

Contact form

- Choosing a selection results in a full page refresh.