Thermal Plates

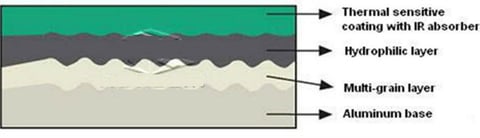

Huida products thermal CTP plates.

The advantages of thermal plate:

- The dot reproducibility is good, the resolution is high, and higher quality prints can be printed;

- The heat-sensitive plate can be fully applied to the existing printing environment and has good printability;

- Easierto use, low sensitivity to natural light, suitable for infrared laser imaging with heat, so users can operate in a bright room;

- Save consumables. When the thermal CTP plate is published and printed, due to its solid dots, clear edges and easy inking, compared with the traditional PS plate, it can achieve better results with less ink and save ink;

- Since the plate uses alkaline potion, it is very beneficial to investment and environmental protection;

- The quality of the generated printing plate is stable. If the thermal plate is to generate an image, it must reach the initial thermal energy threshold, and the thermal energy higher than the initial threshold will not change the shape of the dots. This is the only technology that can control the predicted results, and the quality is easy. control, so as to achieve the stability of publication quality;

- It can be stored, and the thermal plate can be extended to 6 months after exposure and then developed, and the quality has not changed.

The disadvantages of thermal plates:

In the production process of the plate, if the process control of the sensitizer preparation process is not good, the problem of the failure of the heat-sensitive plate will be encountered. But this is the problem of plate manufacturers.

Processless Plate

The processless plate refers to the printing plate that does not need to be washed during the printing process

The advantages of the processless plate :

- No printing process is required when printing plates, which avoids the use of water and chemicals for printing plates, and is more environmentally friendly;

- The use of water, electricity and equipment and the generation of waste are reduced when printing plates, so there is no need to do time-consuming re-measurement, cleaning and maintenance of the processor or cleaning device, saving pre-press time, which is beneficial to enterprises. of;

- Recycled paper and cardboard, as well as alcohol-free fountain solution, can also be used in printing, thus realizing a real green production.

The disadvantages of the processless plate: mainly in the using process

- Try not to expose the rinse-free CTP printing plate in sunlight for a long time in terms of exposure time;

- It is necessary to make a special wooden box for the rinse-free CTP plate during storage, and the wooden box should be painted with reflective paint, and the embedded cover should be covered to avoid light;

- Try to avoid grabbing directly with your hands during the process of loading the plate, and it is recommended to wear gloves when taking it;

- In the process of changing the plate, especially when printing a long version, if the dots are lost or the plate needs to be changed during the development process, the rinse-free CTP printing plate has obvious shortcomings. Because it is developed by the fountain solution and the ink roller of the printing press, at this time, the plate change is likely to cause a large area of the non-inking area to be dirty (ink on the water roller), which is difficult to handle and will cause some losses and Inconvenient, so pay special attention.

- Differences in operating habits: The rinse-free CTP plate needs to be dampened by a water roller, that is, first rely on the water roller, dampen the plate for 2 to 3 minutes, and then rely on the ink roller to transfer the emulsified adhesive layer to the plate paper to complete the developing process, so the printing operator needs to change the original operating habits.