Since the late 1990s of last century, the Chinese printing industry has been driving a period of rapid development in the pre-press digital revolution. This would undermine the conventional printing production techniques of digital idea development that are used in many different sectors of the printing industry. The pre-press-making region has been pushed to the forefront of the digital revolution in this industry, which has been dubbed "changing the fate of Chinese printing," and has emerged as the best of all new production ideas, rising technologies, and competitive equipment stages.

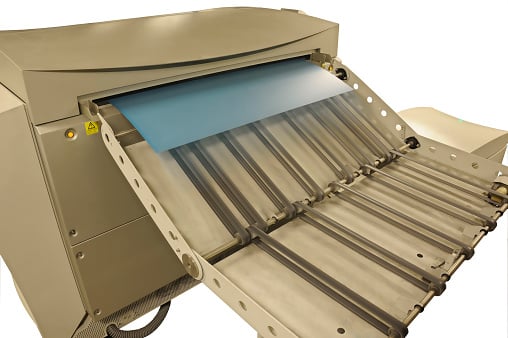

When the set is "digital information, production standardization, and management systematization" in a computer-to-plate (CTP) device, it is most noticeable in many of the modern pre-press tools. The tool's "high-tech, high-quality, high-efficiency" features, advantages of numerous manufacturers trying to become a hot spot, and former first-class printing firm logo and pre-digital pronouns are all things that make it stand out.

But does the presence of a CTP actually indicate the presence of a digital one?

With the advancement of CTP technology, people are discovering that the solution is ambiguous. Many unsuccessful purchase cases have repeatedly shown people the same thing: it is not important to simply introduce CTP equipment to achieve simple, efficient digital production. Instead, it is important to focus on the equipment's performance as well as its business advantages and integration characteristics in order to play the CTP equipment to its fullest potential.

CTP and CTCP What distinction exists between the prepress tools that best reflect the benefits of digital production? So far, the general CTP and CTCP categories of pre-press computer-made plate-making equipment have been established. Although the two technologies provide "prepress production - data transfer - direct plate" one-stop operations and save the film plate creation procedure, from the point of view of technical qualities and actual execution, CTP and CTCP are superior. A significant disparity exists. The evolution and expansion of CTP are known as CTCP.

What Makes Them Different?

-

Using Exposure Materials

While CTP will be digital information in a specific photosensitive layer covered with a unique CTP plate, CTCP will be digital information in the regular PS version.

We are all aware that "items are rare." The criteria for CTP imaging exposure on the media-sensitive layer are highly strict because the CTP laser light source's severe wavelength requirements have a very narrow wavelength range. The CTP plate is overly complicated and more expensive, which contributes to the popularity of the standard PS version and its high production costs. The main source of stress for the purchasing staff in the printing industry is the fact that there are only a few import plate suppliers, like Agfa, Kodak Polylight, Fuji Starlight, and others, who can supply CTP plates. Domestic brands are not only uncommon but the performance and plate of the indicators compared to imports are also considerably different, making it impossible for them to satisfy the needs of standard printing.

Those who are familiar with the printing operators' production know that printing more on each plate than the original half or even double will matter. If a PS version costs 35 yuan and a CTP version costs 70 yuan, small and medium-sized printing businesses will lose 700,000 yuan in earnings every year with an area of 20,000 square meters. Despite the fact that CTP has a great deal of potential economic benefits for the company, these benefits pale in comparison to the stark cost difference.

-

Exposure Technology

Exposure technology is the primary subject matter, regardless of whether it is CTCP or CTP equipment. It is strongly related to both the device's lifespan as well as the quality of the exposure imaging. Exposure to head structure and state mobility has a direct impact on the routine upkeep and maintenance of equipment.

CTCP completes the platform exposure operation by using a short arc UV high-pressure mercury lamp as the exposure light source, digital dot imaging technology, and magnetic levitation drive.

Its exposure head is made up of two components: a high-precision optical part and a control and detecting system for the exposure imaging of contemporary electronic sensor devices. The system can automatically adjust the exposure head's height in response to the printing plate's surface irregularity, resulting in high-quality exposure. When compared to CTP equipment that uses a laser as its light source, CTCP exposure head maintenance is more convenient and simple; regular operators may replace the light without the help of a specialist. Not only does the magnetic levitation drive technology keep mechanical wear to a minimum, but it also significantly lowers the likelihood of equipment failure, resulting in high-quality products with a strong warranty.

This benefit is not offered by the CTP device because daily usage of a mechanical drive will inevitably produce wear and tear, which is unavoidable in any case.

-

Performance of the Printing Process Fusion

The printing process is the plate's primary function, hence the most sophisticated plate-making technique is only useful for printing processes with smooth joints.

Although CTCP and CTP technology can be included in the printing process, the requirements and the outcomes are very different.

The performance of the printability in its printing process and the regular PS version of the printability are both significantly different as a result of the significant differences between the CTP plate coating material and the conventional PS version of the coating material. It is necessary to alter and test the ink balance, press pressure, liquid pH, and surrounding conditions during actual printing. The practice has shown that this is a somewhat drawn-out and challenging process of transition for both the press operator and the manager. The replacement of different printing parameters makes CTP more difficult and speeds up the integration of printing technology, which leads to the recovery of investment costs and longer-term economic benefits.

The advantages of CTCP in the printing process integration are significant. The media's uniformity will guarantee the printing equipment's capacity to function normally. Printing businesses do not need to spend a lot of time and effort matching the medium to the printing press, nor do they need to worry about the printability of modifications brought on by issues. The plate-making and printing processes can complete the mutual financial and economic benefits in a fairly short period of time because of relatively consistent printing characteristics.

Both various CTP plate and CTCP plate varieties as well as their aluminum base plate are available from Henan HUIDA. We can provide you with better pricing because we are a direct manufacturer. Please feel free to ask any questions by leaving a message below.