As new technologies drive the development of the industry, printing production has undergone significant change throughout time. Even if the development of digital media has drastically impacted printed content, printing still plays a key role and is a required medium for organizations of all kinds.

In the evolution of the printing business, computer-to-plate(CTP) imaging systems have been a pioneer and offer several advantages over traditional printing techniques and plate-making. Here, we'll look at why CTP technology is crucial for your custom printing project in offset printing.

CTP: What is It?

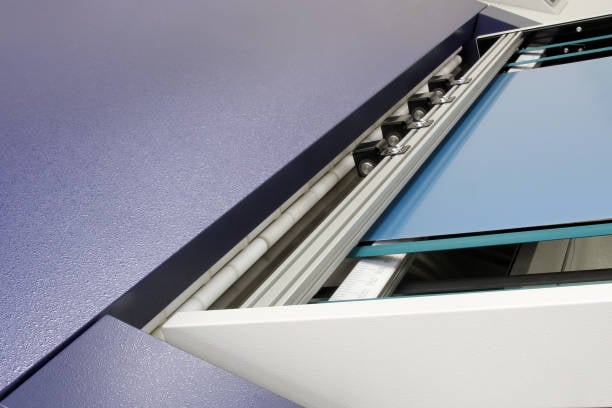

The print design is output on photographic film first in the conventional offset printing process for custom paper boxes, after which the printing plate (often a PS plate) is created. CTF, or computer-to-film, is another name for this imaging technique. But today, everything has changed significantly. In a modern printing facility, artwork developed with desktop layout programs like Adobe Photoshop, Adobe InDesign, and others is output straight onto the printing plate. This artwork is typically in PDF format. This technology is known as CTP.

Key Competitive Advantages of CTP Technology

CTP is superior to traditional plate-making in a number of ways.

- CTP Offers High-quality Work

CTP printing eliminates a step by doing away with the usage of film, which was previously utilized to transfer images to a printing plate, from the process. Scratches, underexposure, and overexposure, which frequently happen with film, are reduced by CTP. Additionally, because film depends on a pin grid that is independently oriented, it is simple for registration mistakes to occur. As plates remain firmly in position, print quality improves in terms of sharpness, detail, and resolution. Over 4 successive separations, CTP devices typically have an average accuracy rate of +/-2.

- CTP Offers Quicker Turnaround

For both your business and your customer, time is money. Reduced production run times and much higher print production outputs are offered by CTP technologies. For instance, plate-setters used in newspaper production may produce up to 300 12-inch plates per hour, while CTP imaging systems used in business can produce up to 60 to B1 plates per hour. Faster consumer delivery times can frequently distinguish print businesses from their rivals and increase client loyalty.

- CTP Technology Has Better Environmental Impact

Environmental standards have gotten stricter in recent years, as every offset print company is aware of. The urge to decrease chemical consumption in the prepress department appears to increase with each new law.

CTP imaging technologies eliminate not just the requirement for the film but also the associated biohazards and chemicals needed for film processing. The most important advancement in CTP technology in recent years has been true chemistry-free thermal CTP, which means no usage of processing chemistry, gum, or fountain solutions to develop the plate.

- CTP procedures are efficient and affordable

By streamlining processes and using CTP, businesses can reduce labor costs and save money. CTP uses fewer resources, employs fewer workers, and generates a lot less trash. The main benefit of CTP is the increase in general productivity brought on by automated technology. These outcomes translate into better quality and higher profit margins, even if your output is only slightly raised.

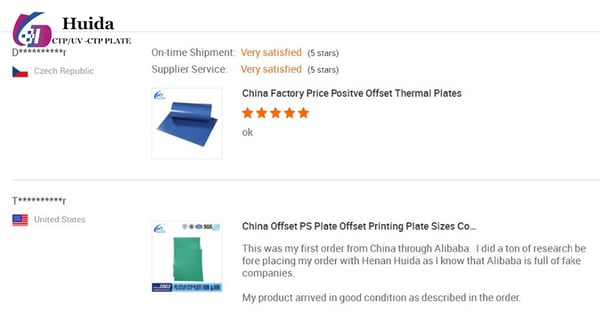

The CTP Tech in HNHUIDA

Henan Huida Print-All Technology Company uses the most recent Computer to Plate technology(CTP), which enhances print quality while saving time and money.

Thermal CTP creates plates without the use of processing chemicals, as I mentioned earlier. Additionally, Plates are produced using thermal CTP, as I indicated earlier, rather than processing chemicals. It is for this reason that HUIDA offers that product. as well as that:

- Design of a Unique Formulation: thermal CTP Plate's sensitive layer has a special formulation structure that sharpens the dot edge created by laser scanning.

- Convenient Operation in a Bright Room: without the use of an additional dark room, the printing plate is imaged and processed in daylight conditions, making it easier and more pleasant for the operators.

- Oxidation Layer With Close-grained: remarkable dot reproduction, and excellent resolution

HUIDA is a top-notch large-scale and specialized printing plate maker. Please do not hesitate to send us an email if you have any questions concerning offset printing.