Digital offset printing machines are becoming increasingly popular among businesses looking for an efficient and cost-effective way to produce high-quality printed materials. With these machines, businesses can produce large quantities of printed materials quickly and with a high degree of accuracy. This article will explore the introduction on the digital offset printing machine, the advantages of using a digital offset printing, factors to consider when buying a digital offset printing, benefits of digital offset printing machines, as well as provide tips on how to get the best results from them.

What is A Digital Offset Printing Machine

The digital offset printing machine has broken through the bottleneck of digital printing technology, and realized the real meaning of one printing, no plate-making, full-color image completion at one time. The extremely low printing cost and high quality printing effect are more economical and convenient than the traditional printing system. The system has a greater market prospect due to its small system investment, digital operation mode and limited space occupation. It is the best supplement to traditional printing and the replacement of traditional printing machines.

How Does A Digital Offset Printing Machine Work

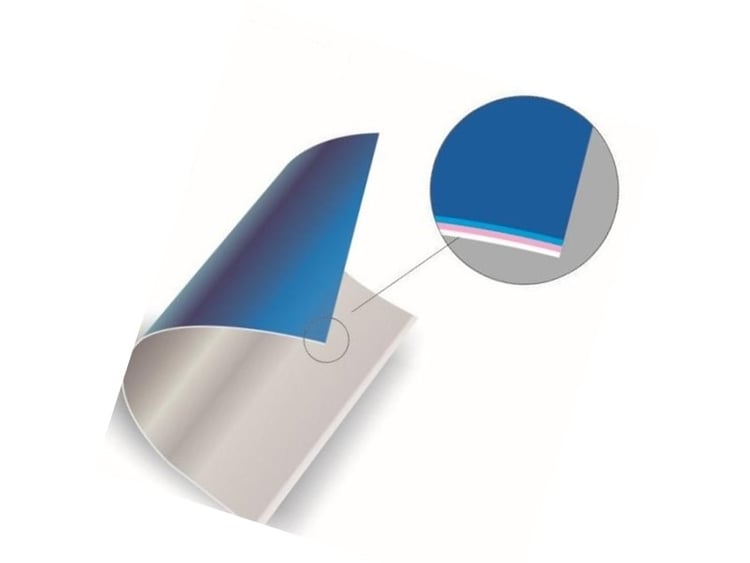

Digital offset printing uses a digital image from a computer to be transferred onto a printing plate. The printing plate is then mounted onto the printing press, where a rubber blanket is used to transfer the image onto the sheet of paper or other substrate.

In the process of offset printing, the ink rollers from the printing press transfer an image file onto a printing plate. This process makes the image areas on the plate ink receptive and water repellant while making non-image areas water receptive and ink repellant. To make sure that the non-image area does not have any ink on it, the image from the plate is printed onto a flexible rubber sheet which is then transferred onto the paper as it passes through the press. The impression cylinder helps in this process and ensures that the image appears on the paper. This printing process is called “offset printing” because the ink is offset to the rubber blanket and then to the paper.

The Advantages of Using a Digital Offset Printing Machine

The advantages of using digital lithography press are as follows:

Simple and convenient operation: There is no need for plate making and repeated color matching process, and the operation is simple and easy to maintain;

Fast printing speed;

Low investment cost, high-speed printing is fully suitable for industrial mass production;

Overcoming the boundaries of materials: It can print any medium within the specified thickness, completely overcoming the traditional printing method that can only use special paper and special specifications. It can use very thin or very thick objects, and its thickness can reach 0.01mm-175mm.

Meet various shapes: Plane, arc and circle;

Height adjustment and batch setting: The height can be adjusted according to the printed object, and the horizontal movable vertical spray structure is adopted, which can easily and freely use various raw materials. After easy placement, it can automatically rise and fall to the appropriate printing height. The automatic feeding time of batch production can be set at will, which saves the steps of repeated computer operation.

Not affected by object material: It can use rich colors to print images on the surface of soft and hard objects such as raw materials (metal, plastic, stone, leather, wood, metal, glass, crystal, acrylic, coated paper, wallet, leather bag, trademark, plaque, etc.). Due to the non-contact between the printing head and the medium surface during spray printing, it will not deform due to heat and pressure, so it can also be printed on raw materials that are easily deformed and soft (such as leather and textiles).

High-precision and perfect printing: Use the special ink produced by the company to make the output image effect realistic and reach the quality of photos. The image is waterproof, sunscreen, wear-resistant and never fades.

Printing format: Meet the requirement of single sheet exceeding A3 (480mm × 330mm), A2(420mm × 640mm),A1(610mm × 1800mm),A0(1118mm × 2000mm).

Rough and inclined surface printing: It can overcome the raw material thickness deviation of up to 5mm. According to the characteristics of the surface of the printed object, the bump drop can be expanded to 5mm at most, and can present a perfect printing effect.

Adopt continuous ink supply system: It is convenient to add ink while minimizing printing costs.

Use special waterproof ink: Clear and perfect printing quality, clear layers, visible color blocks, no color deviation, color mixing, waterproof, wear-resistant, quality non-thermal transfer, silk screen and other traditional processes are comparable.

Ultra-low printing cost: Compared with the existing heat transfer process, it can save more than 80% of the cost.

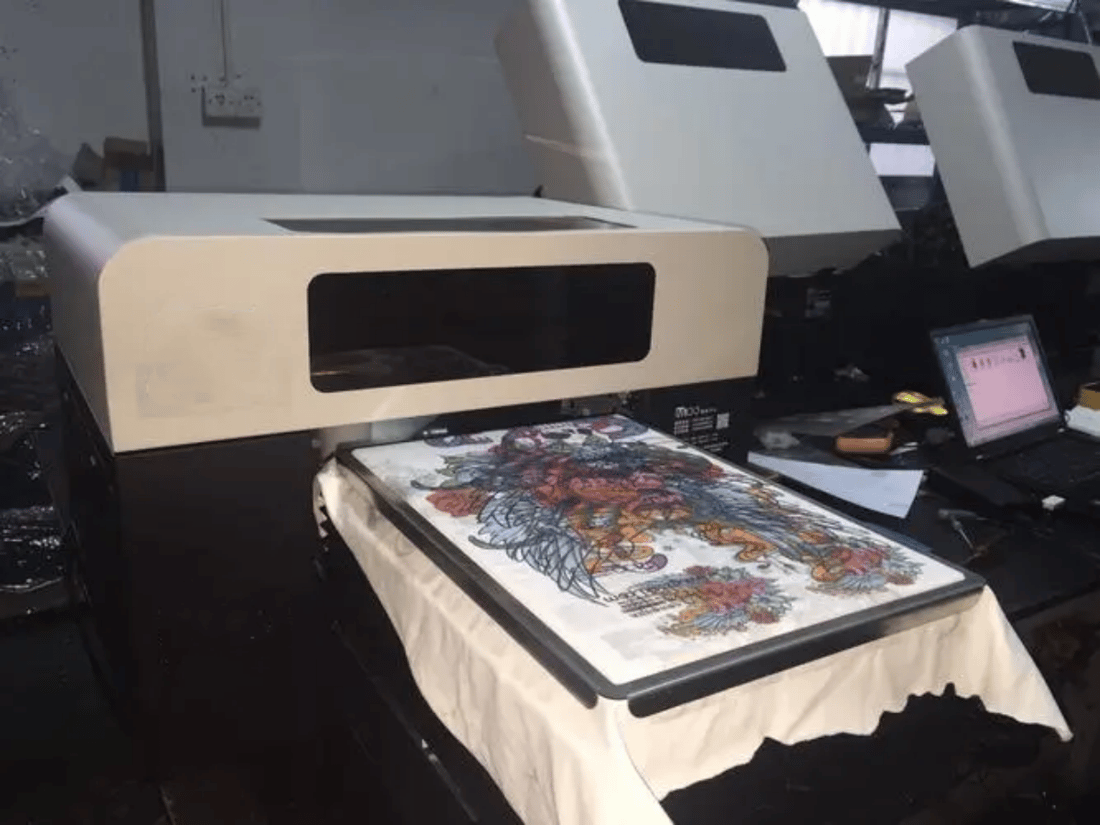

Personalized printing: At the same time, it is very suitable for various personalized color printing services such as T-shirts, pillows (sets), shopping bags, aprons, gloves, cotton socks, handkerchiefs, etc.

Factors to Consider When Buying a Digital Offset Printing Machine

It’s common that there are some factors to consider when buying a digital offset printing machine. As the excellent performance of the digital offset printing machine has been praised by many customers, many industries that rely heavily on printer equipment begin to want to purchase and use this advanced and stable digital printing machine. However, because the offset printing device has a relatively short time to market and many users do not have a deep understanding of it, it is always difficult to select the appropriate and desirable products when purchasing. The following is a brief introduction to the three factors to consider when buying a digital offset printing machine for users who want it.

Try to Choose Products from Brand Manufacturers

The high-quality digital offset printing is an epoch-making product with extremely advanced printing technology and excellent product structure, which also brings high production difficulties and technical requirements for the digital offset printing machine. When selecting the printer equipment, users should try to select manufacturers with large brands and strong technical strength in the printing industry to ensure that the digital offset printing machine bought has more stable performance.

Try to Choose the Ones with Reasonable Selling Price

At present, as the digital offset printing machine is a new member of the printing family, many manufacturers often have large differences in the price of the flat-bed printer in the market due to the different distribution strategies of the manufacturers. Therefore, when buying a digital offset printing machine, you should try to choose products with reasonable sales price and guaranteed product quality.

Be Sure to Choose the Powerful After-sales Service

The digital offset printing machine is usually have much higher quality than ordinary printer products, but in order to make users more comfortable with using the tablet printer equipment, users should consult the seller in detail about the content of after-sales support services of the tablet printer equipment when buying, and be sure to select the equipment produced by the digital offset printing manufacturer with strong after-sales force, which can make users more confident when using it.

Tips for Getting the Best Results from Your Digital Offset Printer

Digital offset printing machine is a high-tech digital ink-jet printing equipment using piezoelectricity, which is leading in many industries.

The domain application effect is very good. In the process of high-quality printing output of digital offset printing machine

Pursue high quality while ignoring the three key points of stability, adaptability of printing materials and process simplification.

- Stability

Stability is a must for digital printing of high-quality digital offset printing machine, and digital offset printing machine to achieve high quality in digital printing, color stability is the most important. An example can be used to illustrate:

When a customer goes to the printing factory to print live parts, he hopes that the quality of printing can be maintained at 90 points or higher, if you score 95 points occasionally and 70 points occasionally, this quality instability will bring trouble to the printing factory. Also in actual production, the change of printing material and equipment wear will affect the universal flat printer to a certain extent, the stability of digital output can only be guaranteed by maintaining the stability of the printing equipment of the digital offset printing machine.

- Adaptability of Printing Materials

In addition to stability, add the second point, that is, the digital printing equipment of the digital offset printing machine qualitative adaptability. At present, the digital offset printing machine can be compatible with printing materials, which are only uniform It can be printed, but if we blindly pursue high quality in the later development and improvement, it can’t reach a very wide range, and material compatibility printing can only achieve high-quality output on one or several media, which is far from enough. The digital offset printing machine equipment must have very good printing effect on a variety of printing materials, which is the key.

- Simplicity of Printing Production Process

In addition to the above two points, the printing process is also a problem that needs to be paid attention to all the time. The reason why printer digital printing technology can grab a piece of market in the traditional printing technology market and develop greatly, the biggest factor of the trend is variable printing, personalized printing and simple process. Such as "UV" newly developed by Anderson, the series digital offset printing machine no longer needs to spray special coating before printing production, UV ray irradiation ink can be cured in 5S, and this process can be directly saved for direct printing. Even it can print printed products with concave and convex feel, but its printing materials can be as extensive as ordinary universal flat printer.

Huida Print-All Technology company, as an advanced and professional manufacturer of producing printing plate, mainly sales CTP, CTCP and PS plates as well as offering ODM/OEMs especially for the offset. For more information, please click the official website link here: https://www.huidaoffsetplate.com/.