Introduction

When it comes to printing, there are several methods available, each with its own set of advantages and limitations. Two popular printing methods often compared are offset printing and flexo printing. In this article, we will delve into the differences between these two techniques, exploring their processes, applications, cost-effectiveness, and environmental impact. By the end, you will have a clear understanding of which method is best suited for your printing needs.

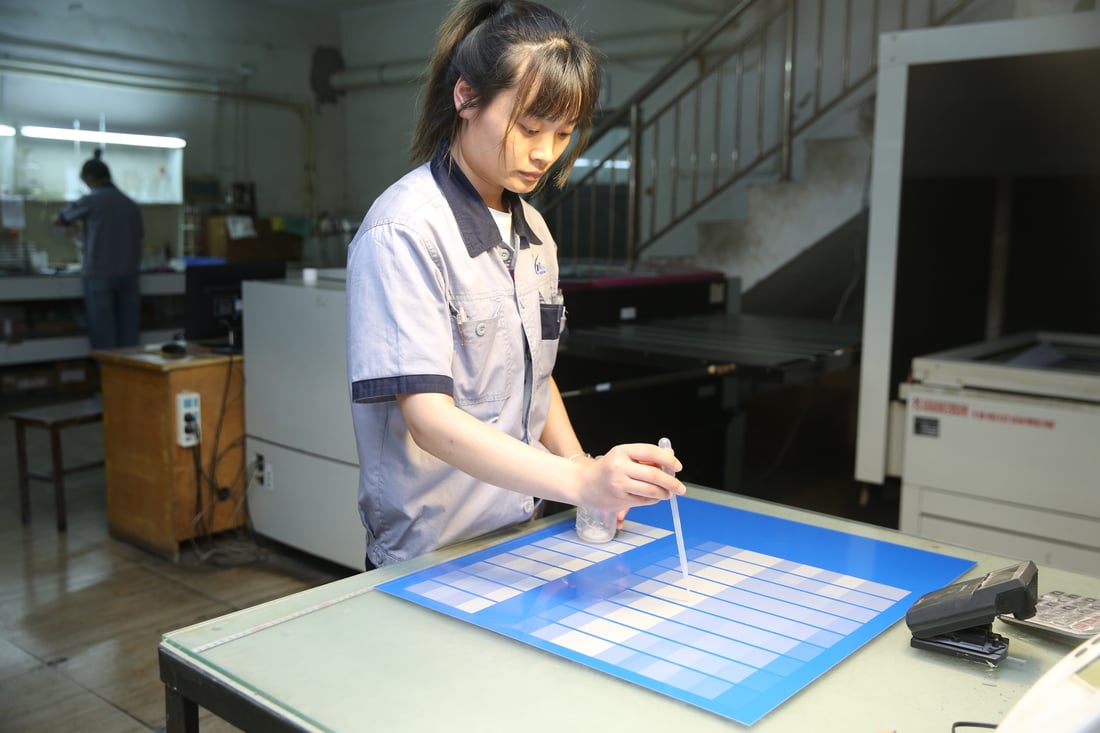

The Offset Printing Process

Offset printing is a widely used printing technique that involves the transfer of an image from a metal plate to a rubber blanket, which is then pressed onto the printing surface. This process is based on the principle that oil and water repel each other. The image areas on the plate are coated with ink, while the non-image areas repel the ink due to the presence of water. The inked image is then transferred to the printing surface, resulting in high-quality prints.

The Flexo Printing Process

Flexo printing, short for flexographic printing, is a versatile method that utilizes flexible relief plates made of rubber or photopolymer. Unlike offset printing, flexo printing uses a direct printing process, where the inked plates come into direct contact with the substrate. The plates are mounted on a rotating cylinder and the ink is transferred to the substrate as it passes through the press. Flexo printing is commonly used for packaging materials, labels, and newspapers.

Quality and Resolution

When it comes to print quality and resolution, offset printing is widely considered superior. It offers sharper and more detailed prints, making it an ideal choice for high-resolution images and intricate designs. On the other hand, flexo printing is better suited for less complex designs and applications where image quality is not the primary concern. The flexibility of the plates used in flexo printing can sometimes result in slight blurriness or loss of detail.

Applications

Offset printing is commonly used for a wide range of applications including brochures, magazines, books, and stationery. Its ability to reproduce vibrant colors and fine details makes it a preferred choice for high-quality prints. Flexo printing, on the other hand, is widely used in the packaging industry for materials such as corrugated boxes, flexible packaging, and labels. The flexibility of the plates allows for printing on various substrates, making it ideal for packaging materials.

Cost-Effectiveness

Cost is an important factor to consider when choosing a printing method. Offset printing is generally more cost-effective for large print runs due to its efficient setup and lower cost per unit. However, for shorter print runs, flexo printing can be a more economical choice. The flexible plates used in flexo printing can be quickly and easily replaced, reducing setup costs. Additionally, flexo printing requires less ink and has faster drying times, further contributing to its cost-effectiveness.

Environmental Impact

In today's environmentally conscious world, the environmental impact of printing methods is a significant consideration. Offset printing is known for its eco-friendly nature as it uses vegetable-based inks and produces minimal waste. The plates used in offset printing are also recyclable. On the other hand, flexo printing relies on solvent-based inks, which can have a higher environmental impact. However, advancements in technology have led to the development of water-based and UV-curable inks for flexo printing, reducing its environmental footprint.

Print Speed and Efficiency

Offset printing is known for its high-speed production capabilities, making it suitable for large print runs with tight deadlines. The process of offset printing allows for continuous printing as the ink is transferred from the plate to the blanket and then to the printing surface. Flexo printing, although not as fast as offset printing, still offers efficient production speeds, especially when it comes to shorter print runs. Flexo presses can be set up quickly and are capable of producing high-quality prints at a rapid pace.

Color Reproduction

Offset printing excels in color reproduction, offering a wide range of vibrant and accurate colors. The use of Pantone or spot colors allows for precise color matching, making it a preferred choice for branding materials. Flexo printing, while capable of reproducing colors effectively, may have limitations when it comes to exact color matching. However, advancements in flexo printing technology have significantly improved color reproduction capabilities, making it a viable option for many applications.

Maintenance and Durability of Equipment

Both offset and flexo printing require regular maintenance to ensure optimal print quality and longevity of the equipment. Offset printing presses typically require more extensive maintenance due to the complexity of the process and the need for precise calibration. Flexo printing presses, on the other hand, are relatively easier to maintain, with simpler setups and fewer components. However, the durability of the equipment depends on various factors such as maintenance practices, usage, and the quality of the machinery.

Conclusion

Offset printing and flexo printing are two widely used printing methods, each with its own strengths and applications. Offset printing offers superior print quality and resolution, making it ideal for high-end materials such as books and magazines. Flexo printing, on the other hand, is more cost-effective for shorter print runs and is commonly used in the packaging industry. When choosing between offset printing and flexo printing, it is important to consider factors such as print quality, application, cost, environmental impact, and production speed. By understanding the differences between these two methods, you can make an informed decision and achieve the desired results for your printing needs.

Huida Print-All Technology company is an advanced and professional manufacturer of printing plates, mainly sales CTP, CTCP, and PS plates as well as offering ODM/OEMs, especially for the offset. For more information, please click the official website link here: https://www.huidaoffsetplate.com/.