CTP direct-to-plate technology is the abbreviation of computer-to-plate in English. It originated in the 1980s and has a history of more than 20 years, but its real application in the printing field has only been for more than 10 years. In 1998, the China Institute of Printing Science and Technology held the first China International Electronic Publishing and Multimedia Exhibition, which introduced the main situation of CTP equipment to the country for the first time. In May 1998, Yangcheng Evening News introduced the direct plate-making system, becoming the first newspaper in China to adopt direct plate-making technology.

The application and development of CTP technology is very rapid. There are two main reasons. First, it breaks through the limitations of the traditional plate-making process, which requires laser phototypesetting to output film and manual imposition and printing. It avoids the need for printing plates in the printing process. Flower marks, dot variations, and inconsistent dots are caused by differences in exposure time, as well as mistakes and errors caused by manual spelling and printing. Second, newspapers are constantly expanding their editions, changing from black-and-white to color, and from single-sided color to double-sided color, which requires higher overprinting accuracy. At the same time, in order to enhance the timeliness of news, it is required to shorten the printing time as much as possible to extend the newspaper news deadline. Therefore, a large amount of page editing must be carried out in a relatively concentrated period of time until plate-making is completed. This makes CTP direct plate-making technology, which can improve newspaper printing quality and save labor, time, and consumables, rapidly become popular in various newspapers.

The CTP system has become popular among users at such an alarming rate. In addition to its good plate-making performance and the advantages of eliminating film, the expansion of its applicable scope is also one of the main reasons. At present, the plate-setting machines on the market can be suitable for large-format and small-format printing sizes, single and two-color printing four-color printing, newspaper printing and commercial printing, etc. Therefore, it is very flexible to use.

For newspaper printing, CTP plate-making technology can also effectively reduce environmental pollution. Due to the streamlined and optimized process flow, it is easy to set up a continuous production line with a high degree of automation. Currently, the domestic newspaper industry is facing fierce competition. The CTP system can save 30-50 minutes in the entire publishing process. When the printing time remains unchanged, the news deadline can be extended, which has a positive significance for increasing the amount of news information on the day and improving the competitiveness of newspapers.

Adopting a CTP system requires certain conditions. From an enterprise perspective, first of all, whether the enterprise has a large plate-making workload. Today's better CTP plate-making equipment has a very fast publishing speed; secondly, the number of films and plates used by the enterprise should be If there are more, the relative savings in film and time will be greater. If there are more short runs, the CTP system will have more advantages; thirdly, the CTP system requires the support of other hardware and should have a certain number of single-fed multi-color offset printing. machine or offset rotary printing machine, etc.

The emergence of a new technology often requires the continuation and development of the old process at the beginning, and finally mutates and completely replaces the original technology, and CTP plates are no exception. The plate problem is a bottleneck in the application of CTP technology. Compared with the traditional PS plate, the CTP plate is more expensive, which leads to an increase in printing costs. If plate costs can be reduced as soon as possible, the number of applications of CTP equipment in domestic newspaper printing will increase significantly.

Computer-to-plate making not only shortens the plate-making process, it can also improve printing quality, improve operational efficiency, provide a wider range of popular services, increase work diversity, etc., making printing more efficient. The good practical application results of many newspapers prove that CTP direct plate-making technology will continue to shine in my country's newspaper printing industry.

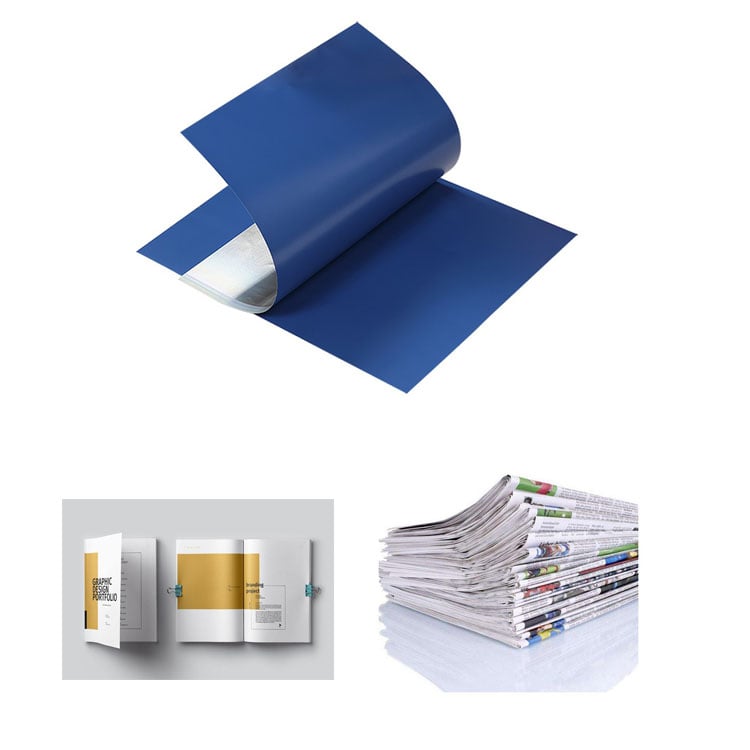

Huida Print-All Technology company is an advanced and professional manufacturer of producing printing plates, mainly sales CTP, CTCP, and PS plates as well as offering ODM/OEMs, especially for the offset. For more information, please click the official website link here: https://www.huidaoffsetplate.com/.